LISEPRO

ındoor skydıvıng manufacturer

Custom systems

We ensure that you fly in the best quality and safety

traınıng

The training of world-class instructors in indoor skydiving and skydiving is based on a combination of sound technical knowledge

Indıvıdual systems for ındıvıdual needs

Our LP mini, LP4.3 Single and Double models are the perfect solution for customized indoor skydiving experiences that can be customized to your specific requirements.

Flıgt area

The “floor” of the flight chamber is made of steel safety mesh with special design flexibility and adjustable connections.

The perfectly round glass panel ensures a smooth airflow without turbulence, unlike polygonal panels with corners that reduce airflow.

Thick glass with special sound-absorbing layers allows you to watch flights up close without earplugs and talk at a normal volume.

Total height 24 m

Glass height 8 m

Minimum diameter 4.3 m

Our technical and engineering capabilities enable us to design and implement any wind tunnel within these specifications according to your requirements.

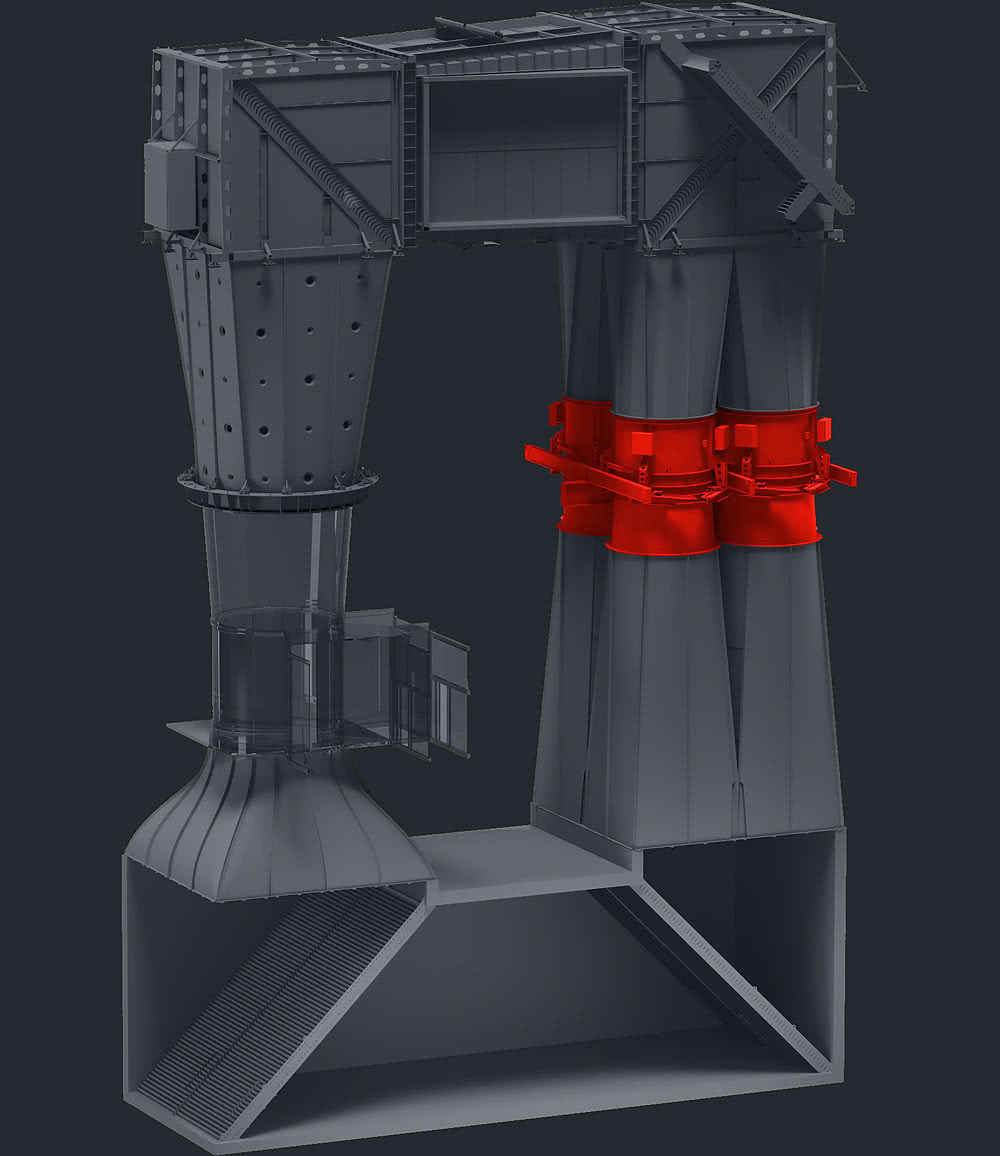

Jet- Fans

LISEPRO

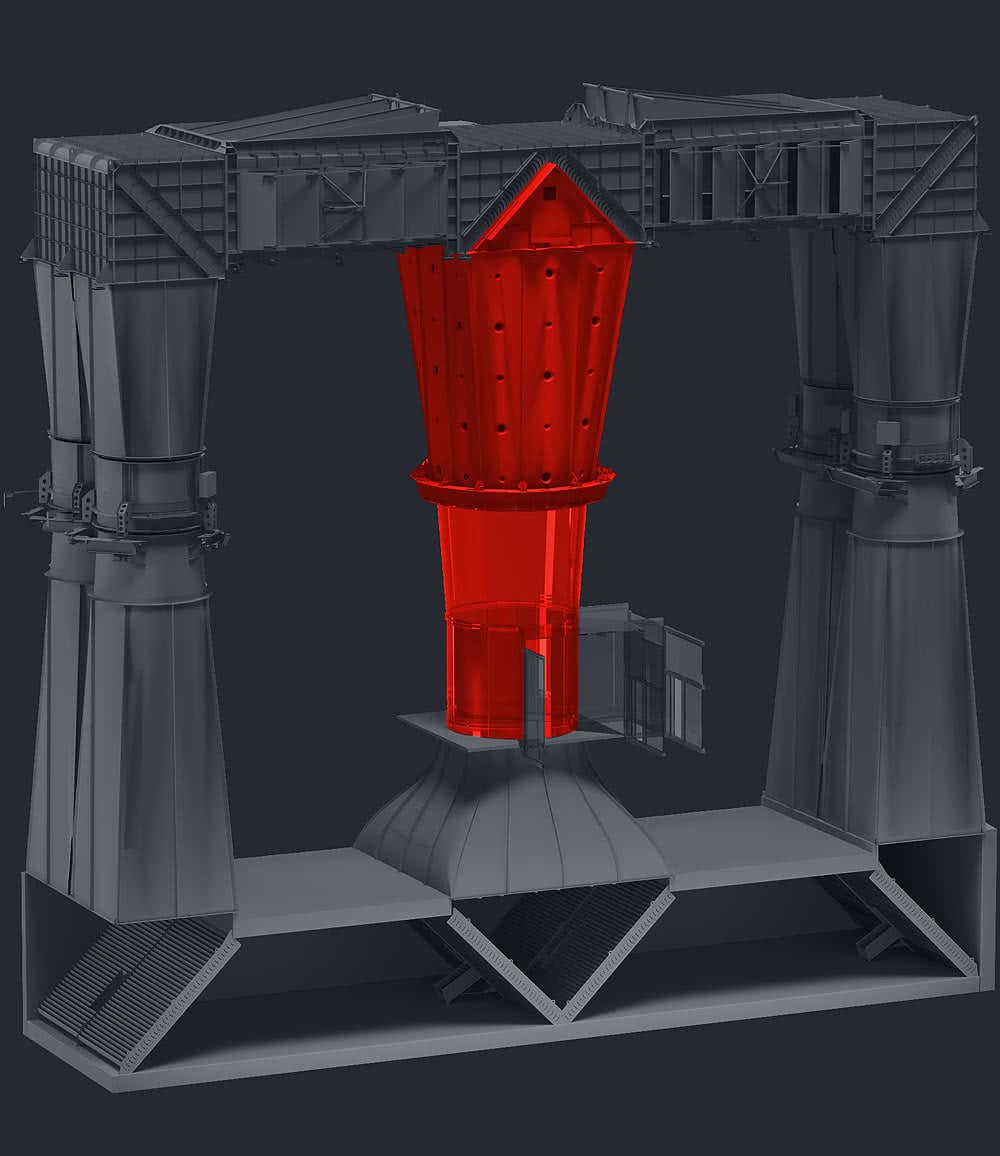

LP4.3 D

the LP4.3 D covers everyone’s needs.

With a maximum wind speed of 320 km/h and advanced safety mechanisms, the LP4.3 D is perfect for all types of indoor skydiving disciplines."

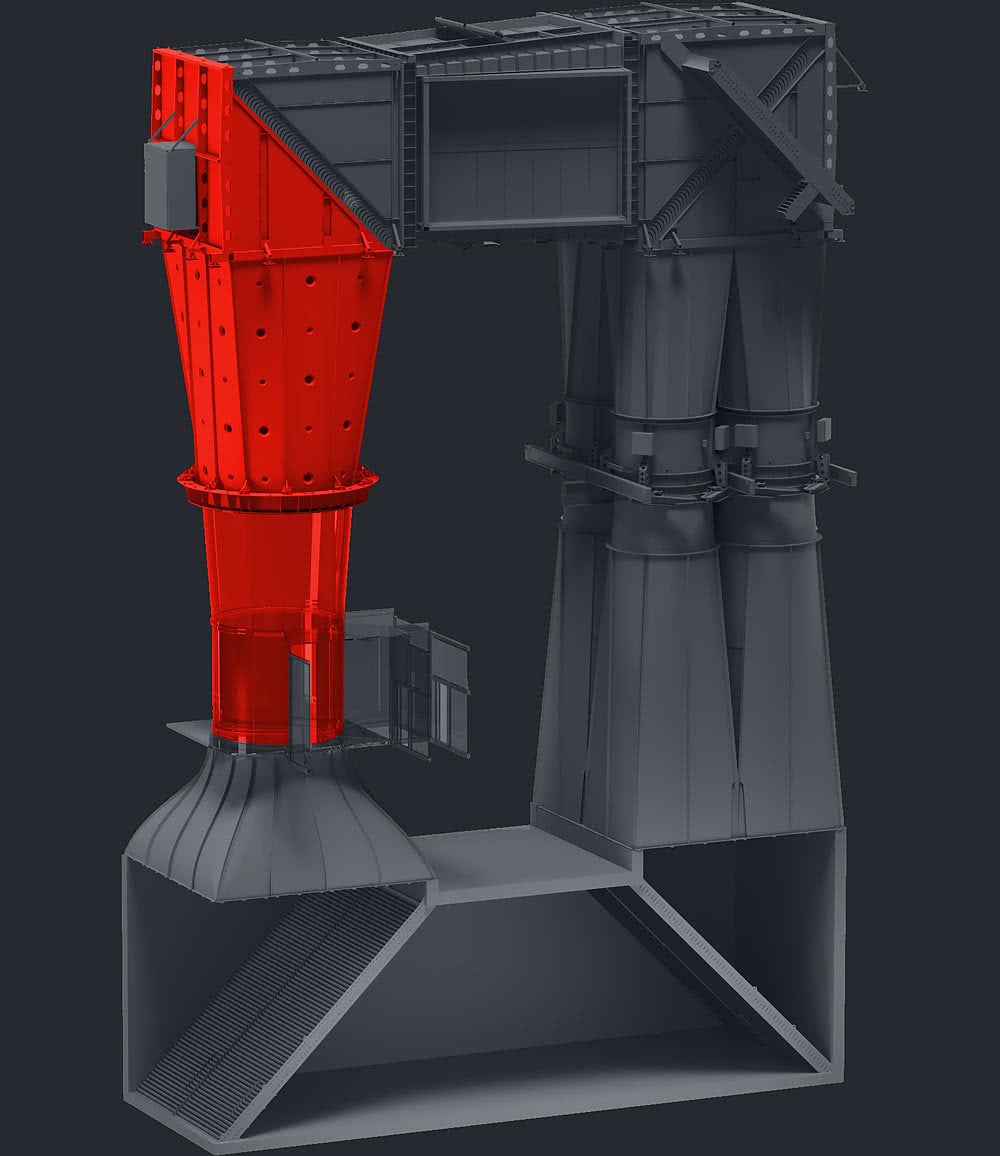

DIFFUSER

Just as every exceptional sailboat is built around a perfectly streamlined shape, the efficiency of a wind tunnel relies on aerodynamic lines optimized to direct unimpeded airflow from the engines into the flight chamber and back. For this simple but challenging task, we have used cutting-edge technology proven over decades of designing and building racing powerboats.

Manufactured with the utmost precision, our GRP composite air ducts guarantee seamless transitions between individual parts of the tunnel. Unlike GRP air ducts made of metal and concrete:

Provides a more precise shape and eliminates turbulence near walls, the main cause of noise and vibration emissions. Relocate wind tunnels to more demanding locations (such as shopping centers or nearby residential areas).

The sandwich structure absorbs sound waves instead of transmitting them through the loop, preventing the uncontrolled resonance peaks common in traditional air ducts, making flying comfortable and safe for children and workers.

It significantly reduces operating and cooling costs by improving the overall aerodynamic design and thus the energy efficiency of the tunnel.

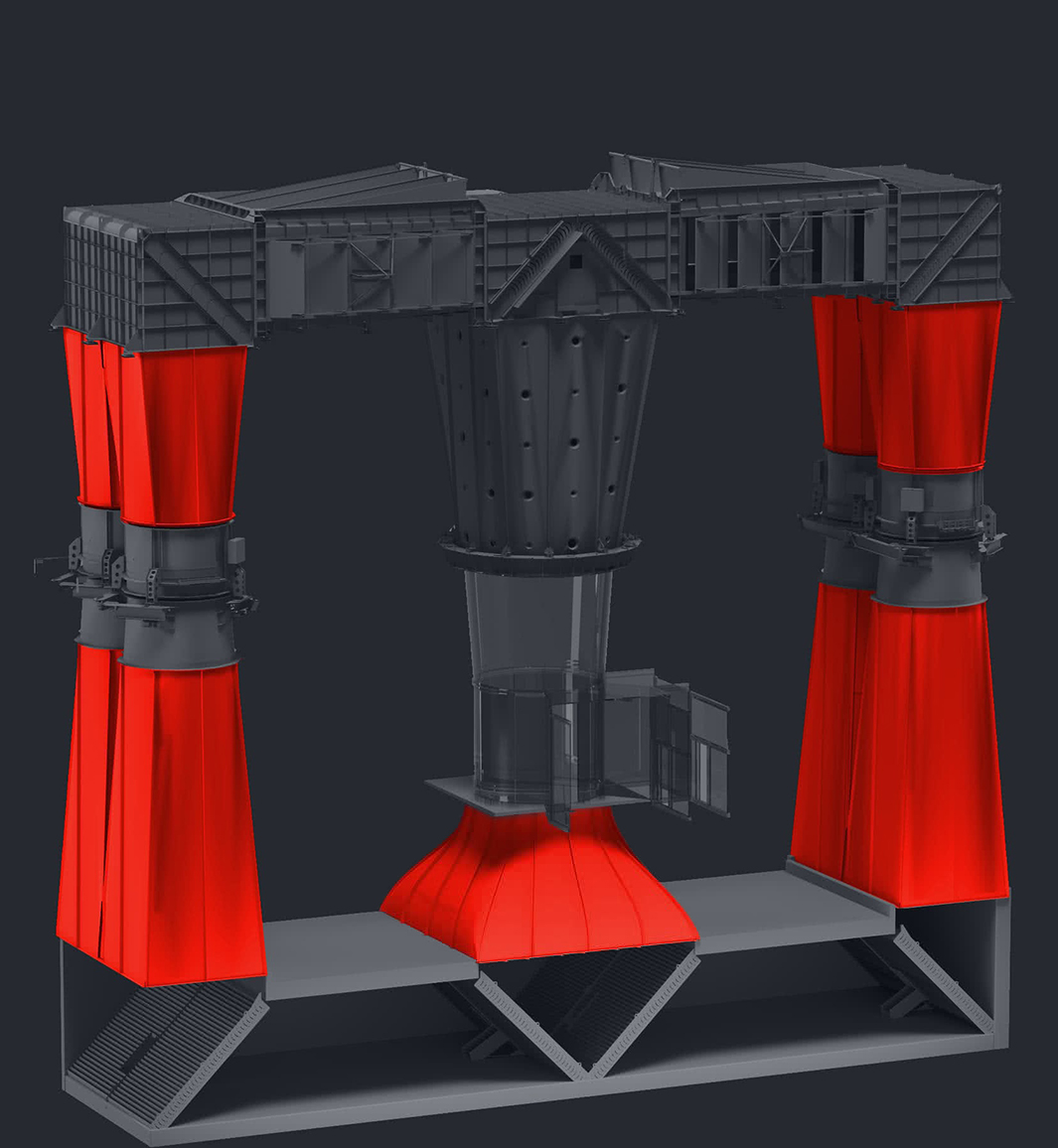

Outlet Rıng

Annular ring will be used to match the air pressure inside the tunnel to the outside to make the tunnel work under zero pressure conditions. Air flows symmetrically into and out of the tunnel without disturbing the main air flow of the tunnel. The duct ring allows the inlet air to be treated and controlled as required (these may include a filter system, a cooling system or a partial or full flow block if required

CLEAR VIEW PANORAMIC GLASS

Our round glass panels are specifically designed to operate in zero and zero pressure conditions. Manufactured through a unique chemical hardening process, the distortion-free faceplates allow viewers and users to see through glass without blind areas or visual interruptions: the experience is almost like flying without glass. The quality of the photos and videos captured from the glass used in the LISEPRO® tunnel will be very clear. The stage area also features floor-to-ceiling glass panels, allowing unobstructed views for faculty and those waiting to take their turn.

hıgh-qualıty Systems wıth a passıon

for years

Specıally Desıgned Guıdance Wıngs

Guider blades are the cornerstone of wind tunnel efficiency. Classic NASA studies; shows that energy losses of up to 30% in a tunnel can occur due to poor guide vane design, insufficient frequency and incorrect installation when installing the vanes. Most importantly, directional blade design can both induce and degrade turbulence, significantly affecting airflow quality.

Lisepro Direction blades are made from extruded aerospace grade aluminum and are calibrated to micrometer precision. The unique X-Large profile of our own design ensures an efficient change of direction without interrupting the airflow, while the reduced distance in the directional blades affects the honeycomb evenly and compensates for the slightest differences in airflow.

Actıve Coolıng System

The Lisepro cooling system is based on uniform airflow cooling through rotating blades. Unlike other wind tunnel technologies, the coolant in our tunnels is fed directly from the central HVAC systems to the hollow rotary fins that act as heat exchangers. This approach eliminates the turbulence that occurs when cooled air is injected into the airstream using traditional systems.

Wind tunnels with cooling systems can be operated in extreme climates and are practically inaudible from the outside. As a result, the system can be placed in the immediate vicinity of residential areas or other areas where external noise emissions are not desired.

Bad Weather Sımulatıon

LISEPRO INDOOR SYSTEMS - FAQ

Total project costs depend on several factors, including the tunnel model, the value of the real estate, and the type of construction (standalone or integrated into a larger project such as a shopping center). We usually see projects coming together in the €1.2 - €10M range; Some will be technology costs, some will be construction.

INDOOR PRODUCTS

USEFUL LINKS

OUTDOOR PRODUCTS

CONTACT

Tel: +90 212 863 2230

Mail: info@lisepro.com